After the concrete pump is constructed, its cleaning work is very important, otherwise it will easily block the pipe. So how to properly clean the concrete pump tube? This is a problem that many construction parties are very concerned about.

Experts pointed out: In order to ensure the normal operation of the construction, it is very important to clean the remaining concrete in the concrete pump tube after the completion of the construction. Otherwise, after the time is long, the concrete is not easy to clean in the dry, then how to clean the concrete pump tube after construction What? Now we introduce the following:

1, preparation work

It is recommended to pump 0.5-1 cubic meters of mortar before cleaning, stop it after pumping all the time, pull the plate valve switch, and then remove the pressure of the accumulator.

2, cleaning method

There are two general methods for cleaning concrete pump tubes: water washing and air washing. It should be pointed out that the valve box and the hopper should be cleaned whether it is washed or air-washed.

It is worth noting that at the end of the washing, it is necessary to pay attention to the water in the pipeline and not to the concrete pouring location, so as not to affect the quality of the concrete. Generally, the method of washing is very simple, and the risk is small, and it is also commonly used.

For air washing, an air compressor is required, and it is recommended to operate in strict accordance with the regulations. The pipe is required to be quite well sealed, but it is not too far away for washing. It can be cleaned in sections at a long distance. Usually this method is cautious and dangerous, so the construction personnel recommend moving away from the exit direction to prevent the pellets or cleaning balls from flying out.

notes for cleaning with water:

Performance parameters of pumps used: pressure not less than 4. 3MPa, flow not less than 180L /min.

The upper pipe connection is made of variable diameter pipe, and the packing material (rubber piston, sponge ball, cement bag roll, etc.) must be packed tightly into the variable diameter pipe one grade higher than the conveyor pipe.

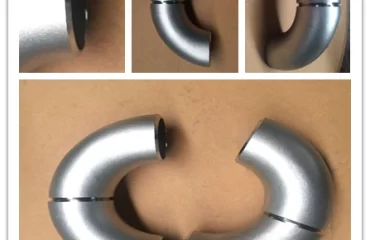

The material isolated in the concrete pump pipe is in rapid collision with the pipe wall. Faster transmission pipe wear. In particular, the bend position of the pipeline, because of the change of the speed direction, the impact of some bending pipes on the coagulation is particularly strong. Therefore, the worst wear of these bending pipes is particularly severe at the end of the pipeline, where the concrete is accelerated to the maximum.

And environmental protection arm bracket pipe is no exception. In order to adapt to different operating environments, no matter which industry is currently in the recommendations of environmental protection. The more and more flexible form of arm support has also become one of the product development trends, especially the wide application of the unilateral support leg technology, which enables the pump truck to adapt to more severe or narrow work space. In addition, product operation intelligence, reliability improvement is also the direction of the country’s enterprises. At present, most of the products of the engine can meet euro Ⅲ Ⅱ or Europe standard. In addition, the concrete cooling device of arm rack pipe is also a device with high energy consumption and pollution. Replacing water cooling with wind cooling will greatly promote enterprises to reduce cost and save water.

Cleaning pipelines and pumps

Major tasks such as line cleaning and pump cleaning need to be handled with care:

Line cleaning

Line cleaning is undertaken with either high pressure water or air, to remove residual concrete in the pipeline. The sudden release of waste concrete under pressure can harm workers and the public.

Check in detail the responsibilities for line cleaning on site in section 4.3.4 of the Concrete Pumping Code of Practice 2005 (PDF, 896.05 KB) and follow the manufacturer’s instructions and employer’s procedures.

The following safety precautions should be followed:

Water rather than air should be used for cleaning and only experienced and trained workers should carryout line cleaning.

The pipeline must not be dismantled for cleaning or other purposes until pressure is relieved. An air relief valve as well as the air entry point to the pipeline is needed to relieve pressure from the system.

The pipeline must be free of internal pressure before disconnecting a pipeline connection or fitting and must not be left unattended until then.

Remove rubber hose at the end of the pipeline and secure all parts of the pipeline to prevent uncontrolled movement during purging.

A device should be attached to the discharge end of the pipeline to catch the cleaning device while the concrete is still flowing.

If a concrete truck bowl is used, concrete lines should be prevented from moving. It is not safe to attach concrete lines to the concrete truck’s ladder.

Workers should be removed from the discharge end while the concrete is under pressure and any workers involved should wear protective clothing.

Pump cleaning

Entanglement, crushing or amputation injuries can occur to workers working with a concrete hopper or pumping device. Workers should avoid placing any part of their body within the hopper. Safety precautions include:

providing a physical barrier at all times to protect people from the moving parts of a hopper

shutting down equipment, where cleaning or maintenance requires entry to the hopper, and using controls to remove any hydraulic or air pressure in order to prevent movement or rotation of parts of the engine

providing workers with instruction, training and supervision when concrete hoppers are cleaned and access to a support person in the immediate area.

You must be logged in to post a comment.