são mais importantes do que nunca para o bombeamento de concreto pronto. Especialmente para projetos com prazos, os tubos de transporte não devem falhar.

Os tubos ST52 de camada única se desgastam em períodos muito curtos de tempo. Isso resulta em altos custos para prestadores de serviços na indústria de concreto pré-misturado devido ao tempo de inatividade devido a reparos, serviço / trabalhos de manutenção ou substituição de componentes.

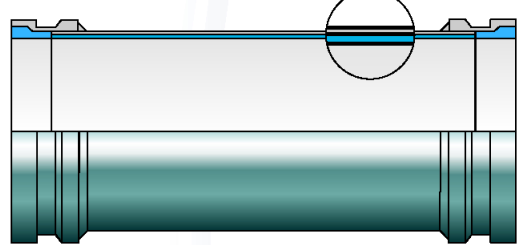

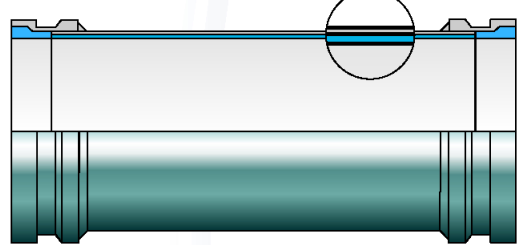

CZPPCO have developed and produced conveying pipes, cotovelos e peças especiais de linha de entrega para bombas de concreto montadas em caminhões, truck mixers concrete pumps or concrete distributing booms since 1998. The two-layer CZPPCO TWIN PIPES achieve a service life, which is significantly longer than ST52 pipes.

Product Specifications Model Description:

| Nome | Estrutura | Especificação de | Peso | Tempo de vida | Impact force | Notched bar impact strength | Maxture work press |

| Normal wear resistant pipe | Único | DN125*3000mm | 48kgs | 6000 – 8000 | ≥45 | ≥27 | 36 bar |

| Economic wear resistant pipe | Único | DN125*3000mm | 45kgs | 18000 – 22000 | ≥47 | ≥28 | 93 bar |

| Construction wear resistant pipe | Único | DN125*3000mm | 45kgs | 20000 – 25000 | ≥47 | ≥28 | 93 bar |

| Diamondwear resistant pipe | Único | DN125*3000mm | 44kgs | 25000 – 35000 | ≥47 | ≥38 | 93 bar |

| W12-5 wear resistant pipe | Gêmeo | DN125*3000mm | 43kgs | 50000 – 60000 | ≥ 42 | ≥25 | 59 bar |

| W12-8 wear resistant pipe | Gêmeo | DN125*3000mm | 43kgs | 60000 – 80000 | ≥ 43 | ≥25 | 59 bar |

| GX350-1 wear resistant pipe | Gêmeo | DN125*3000mm | 44kgs | 80000 – 100000 | – | – | 34 bar |

| GX350-2 wear resistant pipe | Gêmeo | DN125*3000mm | 68kgs | 120000 – 150000 | – | – | 76 bar |

The special hardening process and high-quality welding process ensure that CZPPpipes achieve a service life, which is many times longer than that of commonly available ST52 pipes with the same wall thickness. Boom pipes shall not exceed the specified weight in order to ensure that the stability of the machine is not endangered.

Our pipes are checked for their pressure resistance at regular intervals. The hardness of TWIN PIPE pipes is constant over the entire pipe length so that service intervals can be scheduled more easily. All of our products are manufactured subject to the pump manufacturers’ especificações.

Today, CZPPconveying pipes are used globally.

All CZPPpipes are manufactured in accordance with the weight specifications by concrete pump manufacturers. Conveying pipes for booms are available in two different quality levels. We recommend that you use the CZPP900 XL pipe where you get extreme wear e.g. behind an 10-45° elbow. Those pipes have an extended inlet weld collar to compensate the wear.

| Material

Inlet Outlet |

Double layer, hardened inner pipe

Big Mouth weld collar, hardened inner ring Big Mouth weld collar, hardened inner ring |

||

| Dureza (acc. Rockwell) | Up to 63 HRC | ||

| Nominal diameter (DN) | [mm] | DN 100 | DN 125 |

| Weld collar size | [polegadas] | 4,5″ SK | 5,5″ SK |

| espessura da parede | [mm] | 2,0 + 2,0 | 2,0 + 2,0 |

| (Inside and outside wall) | 2,5 + 2,0 | ||

| Comprimento | [mm] | 100-6000 | |

| Pressão de trabalho (P) | [bar] | 85 | |

| Service life factor*

* Compared with commonly a’ |

5

/ailable ST5 |

2 tubos. Medium c | Concreto. |

concrete pump wear resistant pipe

Você deve ser logado para postar um comentário.