N06625/625 Duplex Steel Elbow

Introduction

N06625, also known as Alloy 625 or Inconel 625, is a nickel-chromium-molybdenum alloy with excellent strength and remarkable corrosion resistance. This alloy is widely used for manufacturing pipe elbows due to its robustness and ability to withstand harsh environments. These properties make it ideal for industries such as marine, chemical processing, and oil and gas.

What is N06625/625 Duplex Steel?

N06625/625 is a superalloy primarily composed of nickel, chromium, and molybdenum. It is known for its high strength, outstanding fatigue and thermal-fatigue strength, oxidation resistance, and weldability. Alloy 625 is particularly effective in environments with high temperature and corrosive elements.

Chemical Composition

The typical chemical composition of N06625/625 is:

- Nickel (Ni): 58% minimum

- Chromium (Cr): 20-23%

- Molybdenum (Mo): 8-10%

- Iron (Fe): 5% maximum

- Niobium (Nb): 3.15-4.15%

- Manganese (Mn): 0.5% maximum

- Silicon (Si): 0.5% maximum

- Carbon (C): 0.1% maximum

- Phosphorus (P): 0.015% maximum

- Sulfur (S): 0.015% maximum

- Aluminum (Al): 0.4% maximum

- Titanium (Ti): 0.4% maximum

Properties

Mechanical Properties

- Tensile Strength: 827 MPa (120 ksi) minimum

- Yield Strength: 414 MPa (60 ksi) minimum

- Elongation: 30% minimum

Physical Properties

-

- Density: 8.44 g/cm³

- Melting Point: 1290-1350°C (2350-2460°F)

- Thermal Conductivity: 9.8 W/m·K

Corrosion Resistance

N06625/625 is highly resistant to:

- Seawater: Excellent resistance to pitting, crevice corrosion, and stress-corrosion cracking.

- Acids: Resistant to a wide range of acids, including sulfuric and hydrochloric acids.

- Oxidation: Maintains oxidation resistance at high temperatures.

- Chloride Ion Stress-Corrosion Cracking: Exhibits significant resistance to chloride ion stress-corrosion cracking.

Applications

Due to its excellent properties, N06625/625 duplex steel is used in various applications, including:

- Marine Industry: Components exposed to seawater, such as heat exchangers, piping systems, and marine hardware.

- Chemical Processing: Equipment exposed to corrosive chemicals, such as reactors, heat exchangers, and pipes.

- Oil and Gas: Components for high-pressure and high-temperature environments, including risers, pipelines, and valves.

- Aerospace: Engine components, turbine blades, and other parts exposed to high temperatures and corrosive environments.

Pipe Elbows

Purpose

Pipe elbows are fittings used to change the direction of flow in a piping system. They are essential for navigating piping routes around obstacles or changing the direction of flow in a controlled manner.

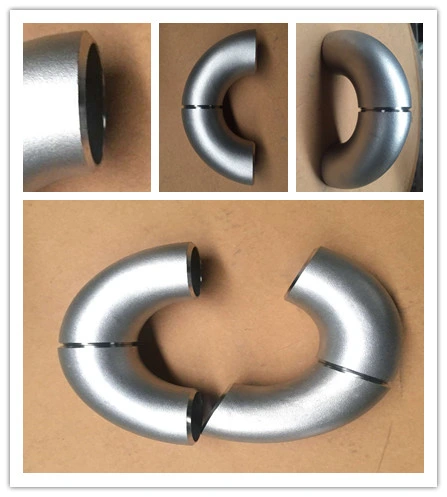

Types

- 45-Degree Elbow: Changes the direction of the pipe by 45 degrees.

- 90-Degree Elbow: Changes the direction of the pipe by 90 degrees.

- 180-Degree Elbow: Creates a U-turn in the piping system.

Manufacturing

N06625/625 duplex steel pipe elbows are typically manufactured using processes such as:

- Hot Forming: Heating the steel to a high temperature and then bending it to the desired angle.

- Cold Forming: Bending the steel at room temperature using mechanical force.

- Welding: Joining sections of steel piping at the desired angle using welding techniques.

Standards and Specifications

Pipe elbows made from N06625/625 duplex steel must meet certain standards and specifications to ensure quality and performance:

- ASME B16.9: Factory-made wrought steel butt-welding fittings.

- ASTM B366: Standard specification for factory-made wrought nickel and nickel alloy fittings.

- ISO 15590-1: Petroleum and natural gas industries — Induction bends, fittings, and flanges for pipeline transportation systems.

Advantages of N06625/625 Duplex Steel Pipe Elbows

- Corrosion Resistance: Exceptional resistance to a wide range of corrosive environments, including seawater and acidic solutions.

- High Strength: Superior mechanical properties that provide durability and reliability in demanding applications.

- Good Weldability: Can be easily welded using conventional welding techniques, ensuring strong and leak-proof joints.

- Versatility: Suitable for various applications across different industries, offering flexibility in design and usage.

Conclusion

N06625/625 duplex steel pipe elbows provide a robust and reliable solution for piping systems in industries requiring high corrosion resistance and mechanical strength. Their excellent properties make them suitable for challenging environments, ensuring long-lasting performance and reduced maintenance costs. By adhering to industry standards and proper manufacturing techniques, these pipe elbows can significantly enhance the efficiency and durability of piping systems.

You must be logged in to post a comment.