Grooved Pipe Fittings by PKPUMPParts: A Comprehensive Guide

Welcome to PKPUMPParts, your trusted manufacturer of high-quality Grooved Pipe Fittings. With years of expertise and a commitment to excellence, we specialize in producing a wide range of grooved fittings designed to meet the diverse needs of industries worldwide. In this detailed guide, we’ll explore our hot-selling types of grooved pipe fittings, their applications, benefits, technical specifications, dimensions, testing procedures, and much more. Whether you’re involved in building water supply systems, fire protection, industrial pipelines, or HVAC systems, our grooved fittings offer unmatched reliability and performance.

Introduction to Grooved Pipe Fittings

Grooved pipe fittings are mechanical connectors designed to join pipes without the need for welding or threading. These fittings feature a groove on the pipe ends, which is aligned with a corresponding groove in the fitting. A gasket is placed between the grooves, and a coupling housing is bolted around the joint to create a secure, leak-proof connection. This innovative design has revolutionized piping systems across various industries due to its ease of installation, reliability, and adaptability.

At PKPUMPParts, we pride ourselves on manufacturing grooved pipe fittings that meet international standards, such as ANSI, ISO, and FM/UL certifications for fire protection systems. Our products are crafted from durable materials like ductile iron, stainless steel, and carbon steel, ensuring long-lasting performance even in demanding environments.

Grooved Elbow

Hot-Selling Types of Grooved Pipe Fittings

Our grooved pipe fittings come in various configurations to suit different piping needs. Below are our most popular types, each designed for specific functions within a piping system:

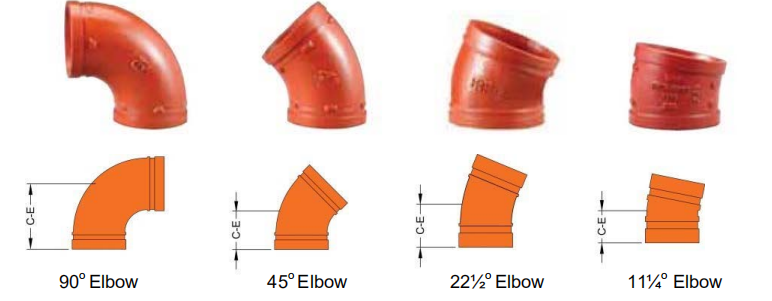

1. Elbows

Elbows are essential for changing the direction of a pipe run. At PKPUMPParts, we offer a variety of elbow angles to accommodate both standard and unique project requirements:

- 90° Elbows: The most common type, used to create a right-angle turn in the piping system.

- 45° Elbows: Ideal for gentler directional changes, reducing flow resistance.

- 22.5° Elbows: Perfect for subtle adjustments in pipe alignment.

- 11.25° Elbows: Specialized fittings for precise directional changes in complex layouts.

These elbows are available in multiple sizes and materials, ensuring compatibility with your specific piping system.

2. Tees

Tees allow a single pipe to split into two separate routes, making them indispensable in branching systems. PKPUMPParts offers:

- Equal Tees: Connect three pipes of the same diameter.

- Reducing Tees: Connect a larger pipe to two smaller pipes or vice versa, accommodating size transitions.

Our tees are engineered for seamless flow distribution and structural integrity, making them a top choice for water supply and industrial applications.

3. Caps

Caps are used to seal the end of a pipe, preventing leaks and protecting the system from debris. Our grooved caps are designed for easy installation and a tight seal, ensuring the longevity of your piping network.

4. Reducers

Reducers connect pipes of different diameters, facilitating smooth transitions in flow capacity. Available in concentric and eccentric designs, our reducers ensure minimal turbulence and pressure loss while maintaining system efficiency.

Applications of Grooved Pipe Fittings

Grooved pipe fittings from PKPUMPParts are versatile and widely used across multiple industries. Here’s a closer look at their primary application areas:

Building Water Supply and Drainage Systems

In urban water supply systems, internal building pipelines, and industrial water networks, our grooved fittings ensure smooth water flow and reliable sealing. They connect seamlessly with various pipe materials, including steel, PVC, and copper, making them a go-to solution for modern infrastructure projects.

Industrial Pipeline Systems

Industries such as chemical processing, pharmaceuticals, food production, and power generation rely on our fittings for their durability and resistance to corrosion. Whether transporting liquids, gases, or slurries, our grooved fittings maintain system integrity under high-pressure and harsh conditions.

Fire Protection Systems

Our grooved fittings are FM/UL-approved for fire protection applications, including sprinkler systems, fire hydrants, and water hoses. Their quick installation and dependable connections ensure that fire suppression systems operate effectively during emergencies.

Air Conditioning and Refrigeration Systems

In HVAC systems, grooved fittings connect water supply pipes, return lines, cooling towers, and pump stations. Their flexibility accommodates thermal expansion, while their robust design enhances heat exchange efficiency and system reliability.

Benefits of Choosing Grooved Pipe Fittings

Why choose grooved fittings from PKPUMPParts? Here are the key advantages that set our products apart:

- Easy and Effective Installation: The grooved design allows for rapid assembly with minimal tools—just align the grooves and tighten the bolts.

- Reliable, Leak-Free Connections: Integrated rubber gaskets provide a secure seal, preventing leaks and reducing maintenance costs.

- Versatility and Adaptability: Compatible with various pipe types and sizes, our fittings suit a wide range of applications.

- Enhanced Strength and Flexibility: Excellent vibration resistance and flexibility accommodate thermal expansion, ensuring system stability.

- Simplified Maintenance: Easy disassembly and reassembly streamline repairs, inspections, and system upgrades.

Technical Specifications and Dimensions

Below are the detailed specifications and dimensions for our grooved pipe fittings. These parameters ensure compatibility and performance in your piping systems.

Parameter Table

| Fitting Type | Material | Size Range (Inches) | Pressure Rating (PSI) | Temperature Range (°F) |

|---|---|---|---|---|

| 90° Elbow | Ductile Iron | 1″ – 12″ | 300 – 1000 | -20 to 250 |

| 45° Elbow | Stainless Steel | 1″ – 10″ | 300 – 800 | -40 to 300 |

| Equal Tee | Carbon Steel | 2″ – 12″ | 300 – 1000 | -20 to 250 |

| Reducing Tee | Ductile Iron | 2″ – 10″ | 300 – 800 | -20 to 250 |

| Cap | Ductile Iron | 1″ – 12″ | 300 – 1000 | -20 to 250 |

| Reducer | Stainless Steel | 2″ – 12″ | 300 – 800 | -40 to 300 |

Dimensions Table

| Fitting Type | Nominal Size (Inches) | Outside Diameter (mm) | Center-to-End (mm) | Weight (kg) |

|---|---|---|---|---|

| 90° Elbow | 2″ | 60.3 | 70 | 0.8 |

| 90° Elbow | 6″ | 168.3 | 140 | 4.5 |

| 45° Elbow | 4″ | 114.3 | 100 | 2.2 |

| Equal Tee | 3″ | 88.9 | 86 | 1.9 |

| Cap | 8″ | 219.1 | 50 | 3.8 |

| Reducer (6″ to 4″) | 6″ – 4″ | 168.3 – 114.3 | 120 | 3.0 |

Testing and Quality Assurance

At PKPUMPParts, quality is our top priority. Each grooved pipe fitting undergoes rigorous testing to ensure it meets industry standards and performs reliably in real-world conditions. Our testing procedures include:

1. Pressure Testing

Every fitting is subjected to hydrostatic pressure tests at 1.5 times its maximum rated pressure. This ensures the fitting can withstand extreme conditions without leaking or failing.

2. Leak Testing

We perform air and water leak tests to verify the integrity of the gasket seal. Fittings are pressurized and inspected for any signs of leakage over a specified duration.

3. Material Testing

Raw materials are tested for tensile strength, hardness, and corrosion resistance using advanced spectrometry and mechanical testing equipment.

4. Dimensional Inspection

Each fitting is measured against precise tolerances to ensure accurate groove dimensions, bolt hole alignment, and overall fit.

5. Vibration and Fatigue Testing

To simulate real-world conditions, fittings are subjected to vibration and cyclic loading tests. This confirms their ability to absorb shocks and maintain stability over time.

Installation Guidelines

Installing our grooved pipe fittings is straightforward, but following proper procedures ensures optimal performance. Here’s a step-by-step guide:

- Prepare the Pipe: Cut the pipe to the required length and groove the ends using a compatible grooving tool.

- Check the Gasket: Ensure the gasket is clean, lubricated, and properly seated in the groove.

- Align the Fitting: Position the fitting over the pipe ends, aligning the grooves.

- Install the Coupling: Place the coupling housing over the gasket and secure it with bolts, tightening them evenly to the recommended torque.

- Inspect the Joint: Verify the connection is secure and leak-free before pressurizing the system.

Why Choose PKPUMPParts?

PKPUMPParts stands out as a leader in grooved pipe fitting manufacturing due to our dedication to innovation, quality, and customer satisfaction. Here’s why you should partner with us:

- Extensive Product Range: From elbows to reducers, we offer a complete selection of fittings for all your needs.

- Custom Solutions: We provide tailored fittings to meet unique project specifications.

- Global Reach: Our products are trusted by clients worldwide, backed by efficient logistics and support.

- Sustainability: We use eco-friendly manufacturing processes and materials to minimize our environmental footprint.

Conclusion

Grooved pipe fittings from PKPUMPParts are the ideal choice for modern piping systems, offering unmatched ease of installation, reliability, and versatility. Whether you’re designing a fire protection system, an industrial pipeline, or an HVAC network, our fittings deliver the performance you need. With rigorous testing, precise dimensions, and a commitment to quality, we ensure that every product meets the highest standards. Contact us today to learn more about how PKPUMPParts can support your next project with our world-class grooved pipe fittings.

PKPUMPParts – Connecting the World, One Pipe at a Time.

You must be logged in to post a comment.