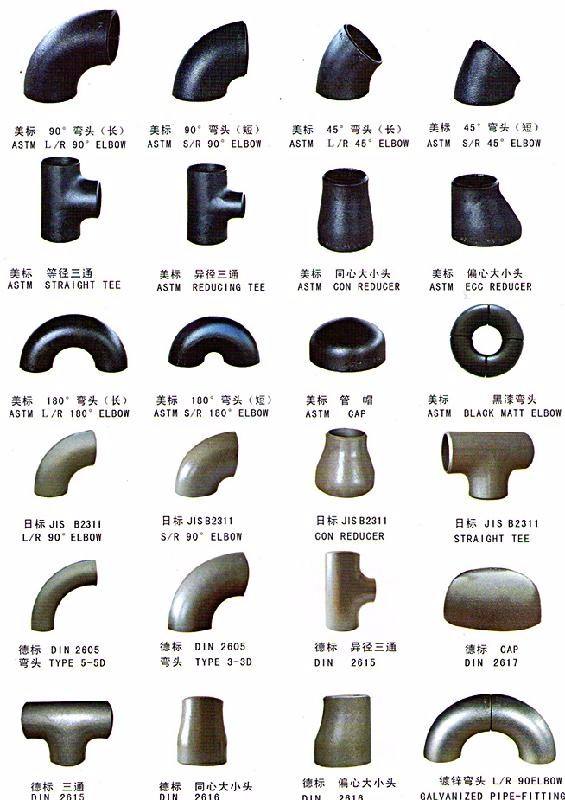

Pipe type:45 Degree,90 Degree,180 Degree Elbow,Long Radius,Short Radius Elbow

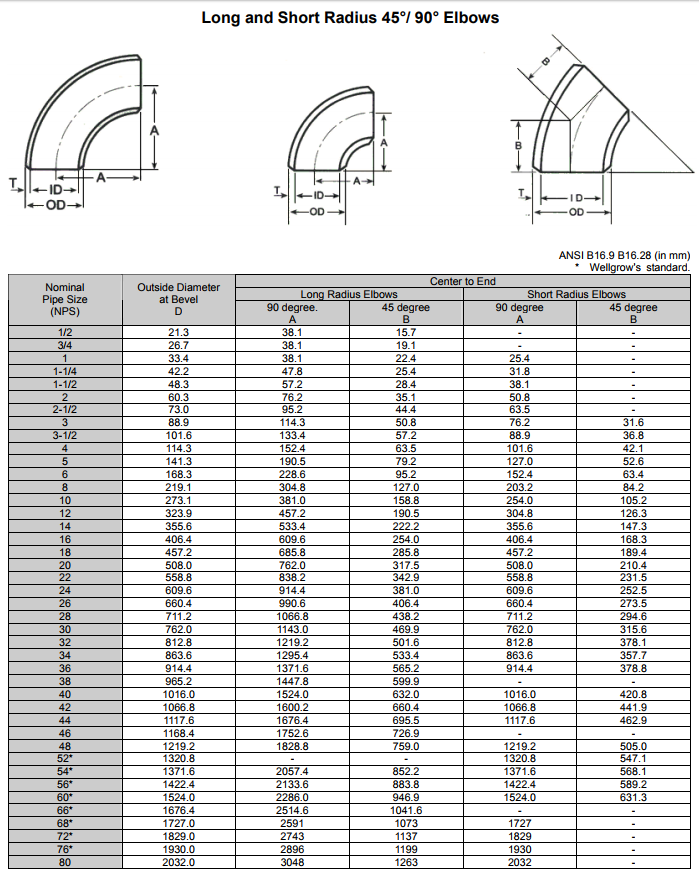

Size:NPS: 1/2”~24”(Seamless), 24”~72”(Welded);DN: 15~1200,

WT:2~80mm, SCH 5~XXS

Bending Radius:R=1D~10D, R=15D, R=20D

Material & Standard:

Carbon Steel — ASME B16.9, ASTM A234 WPB

Stainless Steel — ASTM A403 304/304L/310/310S/316/316L/317L/321 ;

Alloy Steel — ASTM A234 WP1/5/9/11/12/22/91

Ends:Square Ends/Plain Ends (straight cut, saw cut, torch cut), Beveled/Threaded Ends

Packing:Packed in Wood Cabins/Wood Tray

Usage:For conveying gas, water and oil either in the oil or natural gas industries

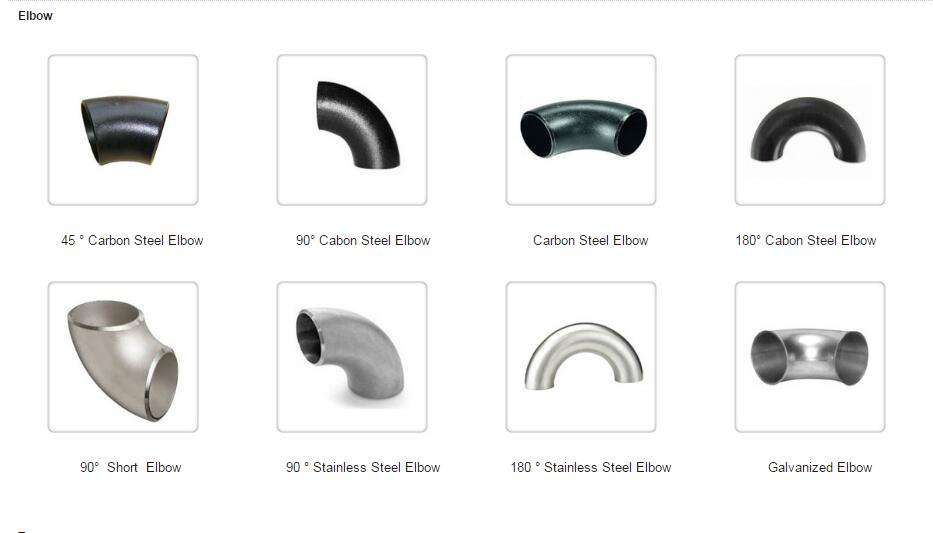

A carbon steel elbow is a type of pipe fitting that changes the direction of the pipe. It’s made from carbon steel, a type of steel that is strong and durable, making it ideal for a variety of industrial applications. Carbon steel elbows are often found in plumbing systems, oil and gas pipelines, and other industrial pipe systems.

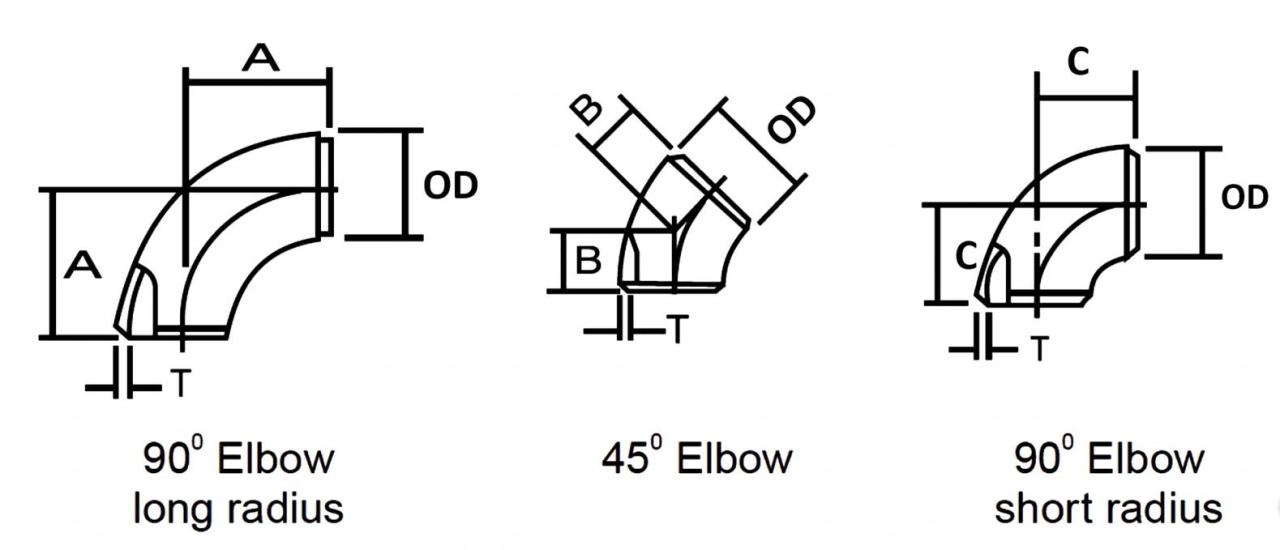

There are two main types of elbows in piping, based on the angle: 45-degree and 90-degree. However, there can also be other angles such as 22.5 degrees, 30 degrees, or 60 degrees, depending on the piping requirements.

Here’s a basic description of a carbon steel elbow:

* **Material:** Carbon steel

* **Types:** 45-degree elbow, 90-degree elbow, other (22.5, 30, 60 degrees)

* **Size:** Ranges from 1/2" to 72" (or even larger for custom jobs)

* **Ends:** Threaded, Socket Weld, Butt Weld

* **Applications:** Plumbing, oil and gas pipelines, industrial pipe systems

* **Standard:** ANSI, ASME, DIN, JIS, etc.

It’s worth mentioning that the carbon content in the steel can affect its properties. Higher carbon content can make the steel stronger and harder, but also more brittle. Low carbon steel, on the other hand, is more malleable and ductile, but not as hard as high carbon steel. The type of carbon steel used in an elbow will depend on the specific requirements of the system it’s being used in.

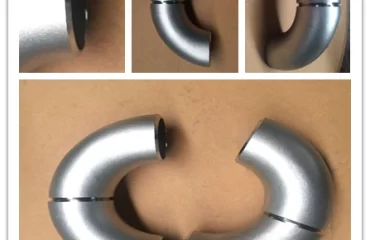

Finally, the surface of carbon steel elbows can be treated with various finishes to improve their resistance to corrosion and to enhance their appearance. Some of the common surface treatments include painting, galvanizing, and coating with anti-rust oil.

What are the different types of elbows in piping?

In piping, elbows are fittings that change the direction of the flow. They are available in a variety of angles and types. Here are some common types of elbows used in piping:

-

90 Degree Elbow: This is the most common type of elbow. It is used to change the direction of the flow by 90 degrees.

-

45 Degree Elbow: This elbow is used to change the direction of the flow by 45 degrees. They are often used in less drastic directional changes than 90 degree elbows.

-

180 Degree Elbow: Also known as a “return elbow,” this type of elbow is used to change the direction of the flow by 180 degrees. They effectively allow the pipe to turn back on itself.

-

Short Radius Elbow (SR Elbow): These are similar to regular elbows, but they have a shorter radius and are often used in tight areas where space is limited. The center-to-face dimension is equal to the nominal pipe size.

-

Long Radius Elbow (LR Elbow): These elbows have a radius of curvature that is 1.5 times the nominal pipe size. They offer less friction and reduced pressure loss.

-

Reducing Elbow: This type of elbow not only changes the direction of the flow, but also reduces the size of the pipe. One end is larger than the other to accommodate the different pipe sizes.

-

Three Dimensional (3D) Elbow: These elbows have a bend that is a little more complex than a simple 90 or 45-degree elbow. They allow for redirection of flow in three dimensions.

-

Street Elbow: This is a type of elbow with a female fitting on one end and a male fitting on the other. It’s often used in tight, close-to-the-wall situations.

Each type of elbow is suited to different applications and requirements, and they come in a range of materials to suit the medium being transported. The choice of elbow depends on factors such as the nature of the fluid, pressure, temperature, and environmental conditions.

-

Introduction

-

Pipe type:45 Degree,90 Degree,180 Degree Elbow,Long Radius,Short Radius Elbow

Size:NPS: 1/2”~24”(Seamless), 24”~72”(Welded);DN: 15~1200,

WT:2~80mm, SCH 5~XXS

Bending Radius:R=1D~10D, R=15D, R=20D

Material & Standard:Carbon Steel — ASME B16.9, ASTM A234 WPB

Stainless Steel — ASTM A403 304/304L/310/310S/316/316L/317L/321 ;

Alloy Steel — ASTM A234 WP1/5/9/11/12/22/91

Ends:Square Ends/Plain Ends (straight cut, saw cut, torch cut), Beveled/Threaded Ends

Packing:Packed in Wood Cabins/Wood Tray

Usage:For conveying gas, water and oil either in the oil or natural gas industries

elbow is a pipe fitting which is used as a connection point between two lengths of pipes to produce a change in the direction of flow in the pipe, usually at an angle of 90°, 45° or 180°. Elbows are also commonly referred as bends, and are available in a range of materials such as stainless steel, carbon steel, alloy steel, nickel alloys, duplex, and cupro nickel.

Also known as 90° bends, 90° elbows are manufactured as SR (Short Radius) elbows and LR (Long Radius) elbows. 45° elbows are typically made as LR (Long Radius) elbows.

The long radius elbows have a center to end distance that is 1.5 times the NPS in inches (R=1.5D), while the short radius is equal to the NPS in inches (R=1.0D).=Short radius elbows are generally used in tight areas, and long radius elbows are used when space is available and flow is more critical. We can also manufacture and supply carbon steel elbows and stainless steel elbows in non-standard size angles such as 60°, 100°, 120° or 150°.

The ends may be machined for butt welding, threaded (usually female), or socketed, etc. When the two ends differ in size, the fitting is called a reducing elbow or reducer elbow.

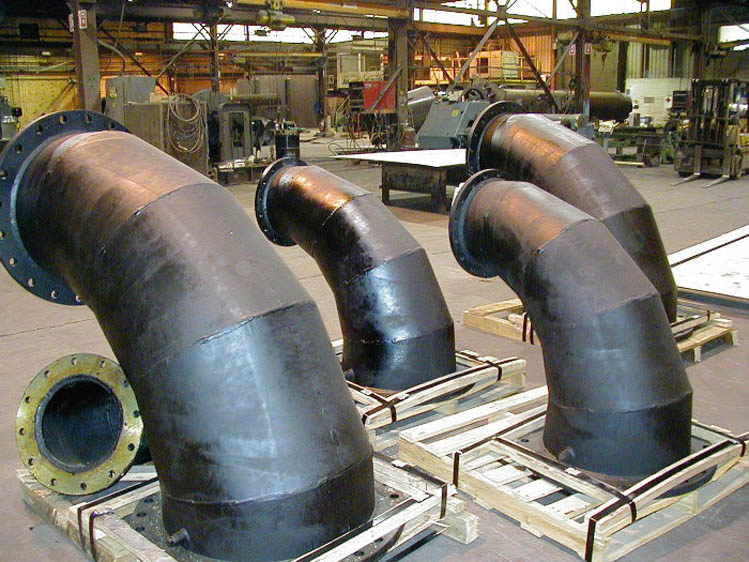

pipe and pipe fitting welded assembling

can be customized according to the customer’s special design and requirements.

Size

-

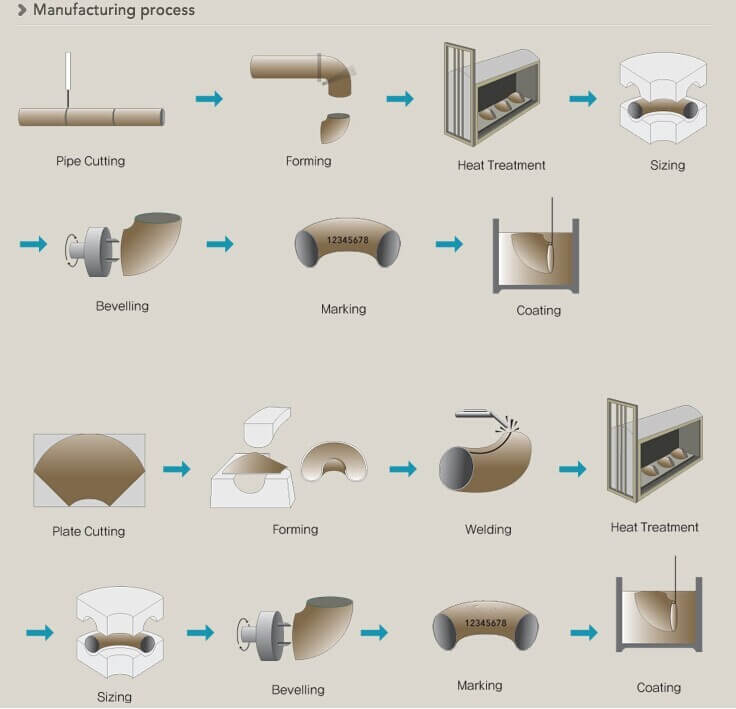

Production Process

-

Packaging

-

You must be logged in to post a comment.